October Scariness – Pumpcoat’s Deep Pit Shaft Repair

How Low can you go? Sometimes in the course of repair work, real life scariness comes into play. Deep holes, rushing water, confined spaces…. These repairs are not carried out by the faint of heart!

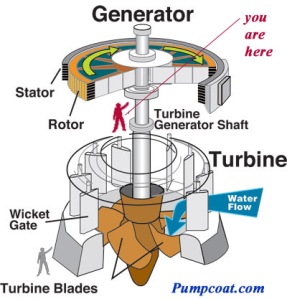

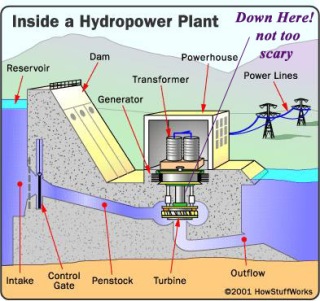

For the past few years, Pumpcoat ~ PCI Contractors have been called in to do repairs on various areas on a large shaft for a hydro-electric facility in Lowell, Mass. We repair a variety of shafts on a regular basis, but what makes this repair unique is that it several stories down in a pit that is regularly filled with rushing water. The shaft is part of the turbine system that generates the electricity for the plant. The entire piece of equipment goes down about 100 feet and has a series of wicket gates that open and close to control the flow of thousands of gallons of water from the dam through. Annually, the pit is de-watered for inspection and repair. Our workers went down approximately 60 feet (about 6 stories) into the pit via ladders and with safety harnesses. Although the water flow had been closed off, they could still hear the eerie sounds of the water many feet beneath them beyond the wicket gates. The walls around them in the pit were slick and slimy from being under water most of the time.

The repair required a first step of sand-blasting certain areas of the shaft. After which an NDE was carried out (NDE stands for Non-Destructive Examination) An NDE can include a variety of tasks such as Visual Examination, Ultrasonic testing, Liquid penetration and others. The Examination results show where there are corroded or pitted areas on the shaft that need repair. Once the NDE had been performed, the area is re-blasted and wiped clean. This brings the surface down to bare metal and removes any excess chips, rust or corrosion so the epoxy coating adheres to the surface.

PCI Workers then applied a coating of Arcor EE-11 Ceramic filled epoxy. This epoxy is perfectly suited for immersion service, and produces a tough, chemical resistant coating. The workers clean up and get back out of the pit, and once cured, the shaft is put back into service.

You hear stories from time to time in the news about repair workers getting hurt or killed on the job. So how does this happen, or rather, how can it be kept from happening?

Several safety measures are taken to prevent accidents on the job. In the case of the deep pit shaft repair, we had a Safety Rescue team onsite whose sole job was to have the equipment at the ready to extract a person if their safety harness failed or they ran into some other issue while at the bottom of the pit. Pumpcoat workers are Confined Space Trained, so they had the necessary skills and Personal Protective Equipment (PPE) for that particular job. PPE can include respirators, suits, gloves, masks, eye & ear protection. Other safety measures can that be used for different projects include air monitoring (for build-up of toxic gases) and air compressors with hoses to blow in fresh air to areas where work is being performed (like the bottom of a tank where other gasses can stagnate). If the equipment normally involves moving parts, a Lockout/Tagout is performed. (A safety protocol that can include a padlock inserted through to physically keep the equipment from being turned on, kind of like a chain through bicycle spokes). Most facilities have additional protocols set up so they know where all personnel & contractors are, and have extraction plans set up in case someone gets hurt. These are just some of the safety measures that are in place to prevent accidents and ensure worker safety.

The truth is that much of what the average person takes for granted – running water, electricity, heat and air-conditioning, etc. is handled by variety of infrastructure equipment that needs to be kept running and in good shape. The invisible hands of modern conveniences are really the culmination of many people who are responsible for keeping the pieces in working order. Some repairs can be scary but proper safety precautions can minimize the risks.